Control. Pressure. Automation.

Zero pressure conveyors offer the control, reliability and automation of a start/stop action. This allows your system to automate start/stop conveyor units. Zero line pressure conveyors can be installed within your existing system or integrated in other Keymas products or a total systems solution.

How zero pressure conveyors work

- The conveyor is fitted with motorised driving rollers along its length to enable the loads to be automatically controlled in ‘zero pressure zones’.

- The stop / start action of these motors is automatically controlled by photocells fitted adjacent to each motor that send information to the onboard ASI control system.

- As the loads are conveyed along the conveyor, the photocells inform the control system that product is present.

- The control unit then checks that the forward zone is unoccupied.

- If the zone is clear, the downstream motor starts thus enabling the product to be passed forward where the action is repeated.

- If however, the downstream zone is occupied then the control system stops the motor immediately under the product until the downstream zone is clear.

- In the event that no loads are present or moving on the conveyor, then zones are stopped effectively saving energy.

Accumulation conveyors – on board controls

Each conveyor section would be factory pre-wired to suit the required zones, requiring ASI control linkage on site and connection to an ASI compatible PLC and including a PILZ relay.

Sensors are the proximity type, vertically mounted on a crosstie. Variable width loads may require alternative sensors to give full effective width coverage.

ASI wiring, motor wiring and any necessary pneumatic piping may be run through the conveyor C section channel which can be effectively closed using Facia. This enables electrical installation to be carried out in a shorter period than experienced with conventional wiring systems.

The on-board controller consists of a node board either enclosed (with Facia) within the side frame (240V motors) or visible with indicator LEDs (24V). Each controller is capable of linking up to 4 zones – each zone may have more than one driving roller, depending on the application. Each driving roller is linked to adjacent slave rollers via electrometric endless driving belts running in special grooves in the rollers.

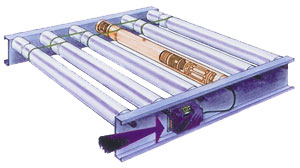

Motorised rollers

Used in the Zero Pressure Accumulation Conveyor is a 24v brushless DC motorised roller offering an ideal option for pre-punched conveyor side frames, where alternative drives would cause obstructions (i.e. within transfer zones) and where a higher zone specification is required (up to IP54).

The torque is adequate to power the zones using a single motorised roller in each zone, incorporating a series of jump belts to link the slave rollers.

Each roller includes a built in circuit board compatible with the 4 motor controller fitted to each conveyor module (linking up to 4 zones).

The 50mm dia roller is zinc plated with grooves for jump belts.

The 11mm across flats hexagonal axle is spring loaded for easy removal and incorporates a keep plate for precise retainment.

Each conveyor module would be assembled with sensors, and wired in our factory requiring PLC control and power supply adding together with site wiring to connect controllers with an ASI cable, a black cable for motor supplies and a further emergency stop cable if required.

The conveyor side channel can incorporate cable runs when used in conjunction with facia.

At present, two speeds are available, 8 metres/minute and 30 metres/minute.

The roller operates on a low voltage and offers accurate stopping by dynamic braking.