In the fast paced world of online ordering and same day delivery, Keymas is helping companies to improve pick rates and accuracy with less manual labour and in less time.

Utilising our K-Store warehouse management system and automated conveyor systems we can deliver a powerful warehouse picking system that can drastically improve operational performance.

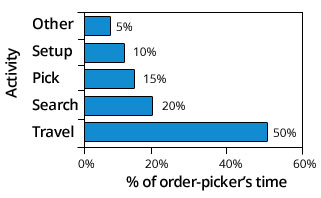

K-Store drastically improves picking rates, pick accuracy and throughput. Analysis from national and international studies have shown that an average picker’s time is split as shown in the graph:

K-Store drastically improves picking rates, pick accuracy and throughput. Analysis from national and international studies have shown that an average picker’s time is split as shown in the graph:

Our picking solutions are designed to reduce the time associated with picking, searching and travelling.

A 750%+ productivity increase can be achieved by introducing automated picking solutions, with the added benefits of increased accuracy and staff accountability.

Conveyors to automate picking

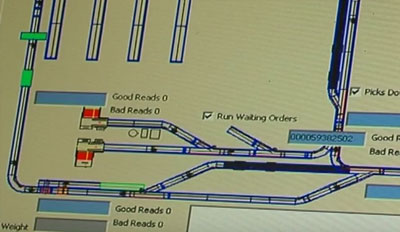

Our automated conveyors will transport the goods straight to pickers, removing the time wasted by pickers walking their own picking routes. When integrated with barcode scanners, goods can be automatically distributed to picking stations, optimising pickers’ time and balancing the pick operation.

Areas where we bring ROI

System directed and transported putaway and picking reduces travel significantly. Over 50% savings in travelling time

Improved order fulfilment rates

Data entry mistakes are cut from 1 in 300 from a good data entry operator to less than 1 in 3 million using barcode scanning

Labour savings through operation inefficiencies

Improves tracability and tracking

Components of our warehouse picking system

Pick Routing

Pick Routing

- Automatically distributes orders throughout the warehouse in order to optimise picker efficiencies

- The system scans the barcode then distributes to picking stations throughout the warehouse thereby balancing the picking operation

- Automatically balances the pick operation

- Optimises picker time

- Minimises picker walking time

Scanners

- Arm wearable terminals with finger scanners leaves the pickers hands FREE to pick the actual product without worrying about the scanner gun

- Tells the picker which item to pick

- Tells the picker the number of items to pick

- Putaway, replenishment and stock checking operations

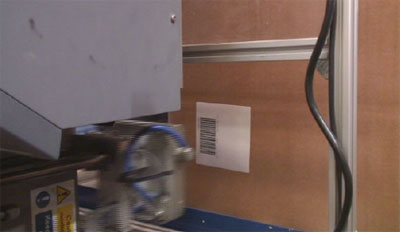

- Automatically applies unique routing barcode

- The printed label automatically associates an order reference with unique box

- No need for manual intervention

- Only printed when required by the system

- Enables full track and trace of orders in the warehouse

Automatic document feed/Pick list

- A pick list is automatically printed and dropped into the box

- The system automatically carries out quality checks on an order prior to despatch

- Checks number of items picked and cumulative weight to ensure correct order fulfillment

- Prevents incorrect order being dispatched

- Can be used to carry out quality checks on picked orders

- Measures picker accuracy

- Automatically prints and applies dispatch label containing all the delivery information

- By scanning the boxes unique routing barcode, the system accesses the order database and automatically prints and applies the delivery label

- Saves time

- Increases delivery accuracy

- Prevents delivery inaccuracy such as human error

- Sorting into despatch lanes ready to be scanned and loaded onto pallets

- Saves time

- Increases delivery accuracy and traceability