UCH Logistics is a dynamic, customer focused provider of specialist transport services to the airfreight industry. Serving this industry for more than 10 years, we have built a reputation for offering reliable time-sensitive and next day deliveries at affordable prices.

Working with UCH, Keymas offered a tailored version of it’s advanced warehouse management system, K-Store. Chris Barton, Technical Director, stated that “We work with companies and take the moduler aspect of K-Store and fit it to the project requirements to offer the customer a solution that fit’s their business. For this project we worked with UCH to customise the solution.”

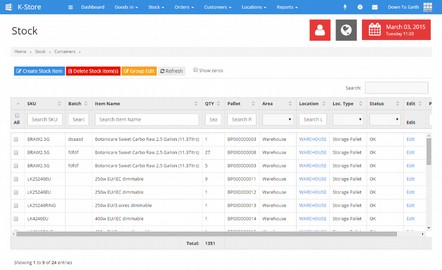

The solution

Using barcode scanners and android tablets the solution gave real-time goods in, storage and retrial. As well as the ability to take photos of the products to store to show customers of UCH.

Goods in

Information entered and labels created to attach to the items

Goods receipt note generated

Extra information recorded such as hazardous and photos taken with tablet

Item labels scanned and then operator puts and scans the location.

This information is available to see in real-time in the K-Store system.

Despatch

When despatched items are scanned out and manifests created. All the scanning is logged and information available in real-time to offer traceability for any queries that are raised. This can be seen by management and customer service operators to have warehouse knowledge from their computer.

Specialty modules

UCH needed to have consignment security documents that are created to an international standard from the system. This meant that creating PDF’s and print outs that complied to airway industries standards. Allowing UCH to digitally produce consignments as they are processed through X-Ray and other security checks.

The information is captured on the barcode touch scanners as well as who is doing the security check and then this information compiled to be sent with the shipment to the airport.

Benefits of the solution

Using K-Store with barcode scanners and tablets has given a number of benefits. The main ones being traceability on the movement of items in and out of the storage warehouse. Knowing where customers items are in the warehouse and also what’s in storage and where all available live is a big benefit.

The other main benefits are in the reduced time of double entry of data that is done with manual systems. So the process that operators go through has been optimised to get the optimal speed along with accuracy of the information.

We can provide expert advice and bring our knowledge and experience to your project.

Discuss your project